Key Components of CNC Machines

Leave a CommentYou may also like:

Timeless Tools: The Standard Modern Lathe

Racer Machinery International: Journey Through Generations

Ontario Made Expertise for the Next Generation

A CNC (Computer Numerical Control) machine is a marvel of modern engineering, capable of transforming raw materials into precise components with unmatched efficiency. At the heart of these machines lies a complex interplay of components, each playing a vital role in the manufacturing process.

The Seven Pillars of CNC Machining

-

Machine Control Unit (MCU): The MCU is the brains of the operation, interpreting G-code instructions and translating them into electrical signals that control the machine’s movement. It’s the central hub that ensures precision and accuracy in every operation.

-

Drive System: The drive system, comprising motors, gears, and belts, is responsible for powering the machine’s movements. It ensures that the cutting tool and workpiece are positioned with utmost precision, enabling intricate and complex machining tasks.

-

Machine Tool: The machine tool, typically a spindle holding various cutting tools, is the physical implement that shapes and removes material. Its movement, controlled by the MCU and drive system, determines the final shape and dimensions of the workpiece.

-

Feedback System: The feedback system, equipped with sensors like encoders and linear scales, constantly monitors the machine’s position and movement. It provides real-time data to the MCU, allowing for instant adjustments to maintain accuracy and prevent errors.

-

Bed and Table: The bed provides a sturdy base for the entire machine, while the table serves as the platform for the workpiece. The table can be moved along different axes, enabling precise positioning of the material relative to the cutting tool.

-

Cooling System: The cooling system plays a crucial role in maintaining optimal operating conditions. It dissipates heat generated during the machining process, preventing overheating and ensuring the longevity of the machine and cutting tools.

-

Input Devices: Input devices, such as computers, keyboards, and USB ports, allow operators to input G-code programs and control the machine’s operations.

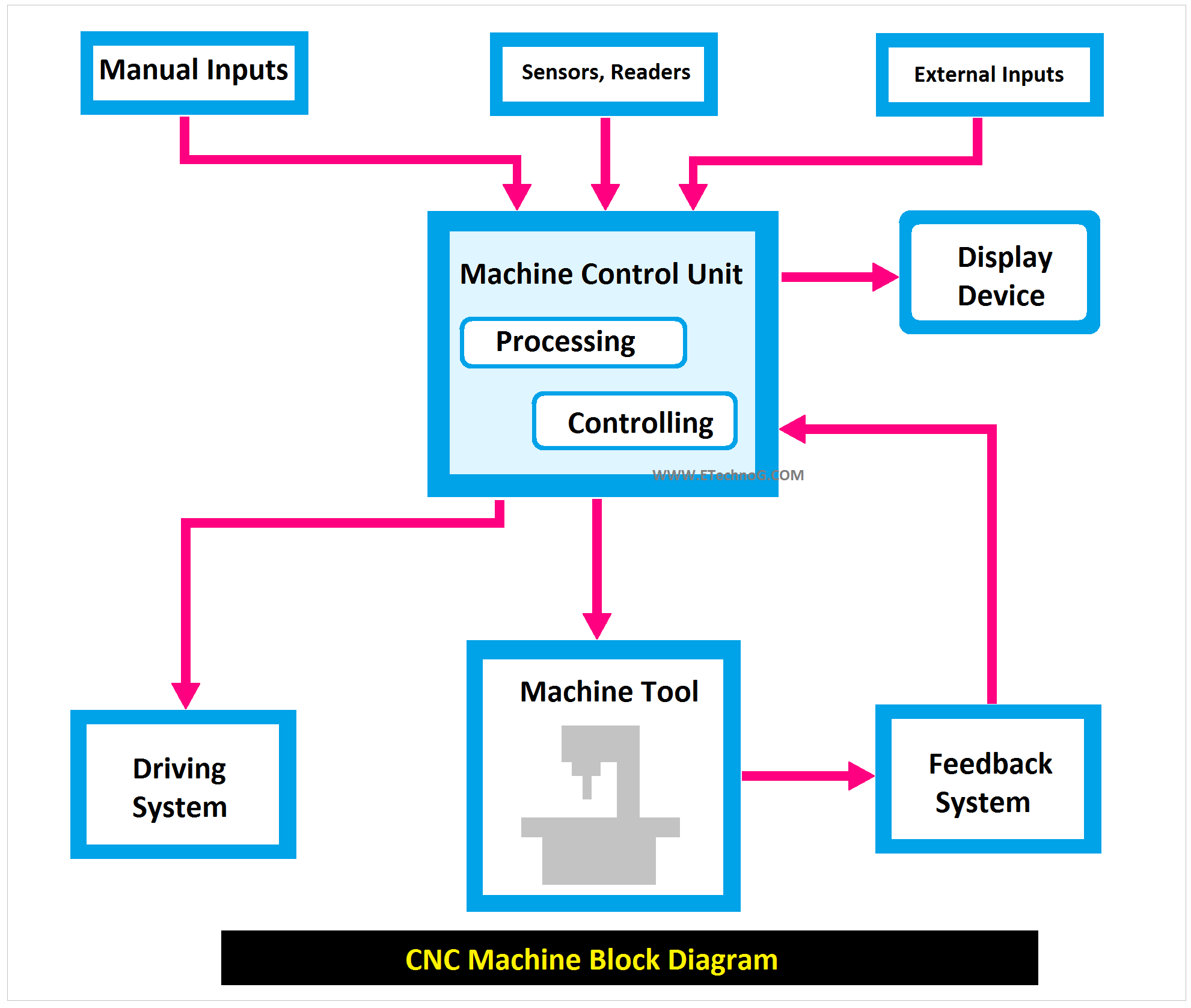

Understanding the CNC Block Diagram

A CNC block diagram provides a visual representation of how these components interact. It typically includes:

-

- Input Block: Represents the devices used to input G-code programs.

- MCU Block: The central processing unit that interprets G-code and controls machine movements.

- Drive System Block: Includes motors, gears, and belts that power the machine’s motion.

- Machine Tool Block: Represents the cutting tool or spindle that performs machining operations.

- Feedback System Block: Monitors machine position and movement, providing real-time data to the MCU.

- Bed and Table Block: Represents the foundation and workspace of the machine.

- Cooling System Block: Indicates the system that manages heat and lubrication.

By understanding the intricate interplay of these components, one can appreciate the remarkable capabilities of CNC machines. From simple to complex, CNC technology continues to revolutionize manufacturing processes, driving innovation and efficiency.

CNC Machine Safety: A Comprehensive Guide

Leave a CommentYou may also like:

Timeless Tools: The Standard Modern Lathe

Racer Machinery International: Journey Through Generations

Ontario Made Expertise for the Next Generation

CNC machines are powerful tools that can significantly increase productivity and precision in manufacturing. However, they can also be dangerous if not operated with caution and respect. Here are some essential safety precautions to keep in mind when working with CNC machines:

General Safety Guidelines

- Training and Supervision: Always ensure you have received adequate training and are supervised by a qualified instructor.

- Machine Familiarization: Thoroughly understand the specific machine you’re working with, including its controls, emergency stop procedures, and safety features.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as safety glasses, hearing protection, and sturdy closed-toe shoes.

- Secure Workpiece: Ensure the workpiece is securely clamped to the machine table to prevent it from moving during operation.

- Tool Condition: Use only sharp, undamaged tools.

- Emergency Stop: Know the location of the emergency stop button and how to use it.

- Machine Maintenance: Regularly inspect and maintain the machine to ensure it is in good working condition.

Specific Safety Precautions

- Power On/Off: Follow the correct procedures for powering on and off the machine.

- Program Verification: Verify your program for accuracy and safety before running it on the machine.

- Tool Changes: Perform tool changes only when the spindle is stopped.

- Machine Operation: Keep hands and other body parts away from moving parts during operation.

- Chip Removal: Use appropriate tools to remove chips and debris. Never use compressed air.

- Workplace Safety: Maintain a clean and organized workspace.

- Emergency Procedures: Be familiar with emergency procedures, such as fire safety and first aid.

Additional Tips

- Focus and Awareness: Stay focused and alert while operating the machine.

- Avoid Distractions: Minimize distractions, such as phone calls or conversations.

- Report Issues: Immediately report any safety concerns or machine malfunctions to your supervisor.

By following these safety guidelines, you can significantly reduce the risk of accidents and injuries while operating CNC machines. Remember, safety should always be the top priority.

Two Spindle Machines: Boosting Productivity

Leave a CommentYou may also like:

Timeless Tools: The Standard Modern Lathe

Racer Machinery International: Journey Through Generations

Ontario Made Expertise for the Next Generation

Two-spindle CNC machines have revolutionized the manufacturing industry by offering significant advantages in terms of productivity, efficiency, and part quality. By incorporating two spindles, these machines can perform multiple operations simultaneously, reducing cycle times and increasing output.

How Two-Spindle Machines Work

-

- Simultaneous Machining: The primary and secondary spindles can work on different parts simultaneously, maximizing machine utilization.

- Part Transfer: Parts can be automatically transferred between the two spindles, enabling back-working operations and reducing handling time.

- Y-Axis Machining: The Y-axis capability allows for additional machining operations, such as drilling, tapping, and milling.

- Live Tooling: Live tooling enables complex machining operations on both the main and secondary spindles.

Types of Two-Spindle Machines

-

Twin-Spindle Machines:

- Both spindles have identical capabilities and specifications.

- Ideal for high-volume production of identical parts.

-

Dual-Spindle Machines:

- A primary spindle and a secondary spindle with the same chuck size and through-bore capacity but different horsepower.

- Suitable for a wider range of part sizes and complexities.

-

Two-Spindle Machines with Facing Spindles:

- The spindles face each other, allowing for efficient part loading and unloading.

- Well-suited for high-precision and high-volume production.

-

Two-Spindle Machines with Non-Facing Spindles:

- The spindles do not face each other, requiring a manual or gantry-style loading system.

-

More flexible for a variety of part configurations.

Applications of Two-Spindle Machines

Two-spindle CNC machines are highly versatile tools used to produce a wide range of precision components for various industries, including medical and automotive. In the medical field, these machines are employed to manufacture intricate surgical instruments like scalpels, forceps, and clamps, as well as medical implants such as joint replacements and dental implants. Additionally, they are used to produce components for diagnostic equipment like MRI and X-ray machines, and medical devices like pacemakers and defibrillators.

In the automotive industry, twin-spindle CNC machines are used to produce critical engine components such as cylinder heads, blocks, crankshafts, and camshafts, as well as transmission components like gears and shafts. They are also used to manufacture suspension parts like control arms and ball joints, and body parts like doors and hoods.

Benefits

- Increased Productivity: Simultaneous machining and automated part transfer reduce cycle times.

- Improved Part Quality: Fewer handling operations minimize the risk of damage and improve accuracy.

- Reduced Labor Costs: Automated operations reduce the need for manual labor.

- Lower Operating Costs: Efficient use of machine time and reduced energy consumption.

- Enhanced Flexibility: Adaptable to a wide range of part geometries and materials.

By understanding the different types of two-spindle CNC machines and their capabilities, manufacturers can select the optimal machine for their specific production needs, ultimately driving efficiency and profitability.

The Power of DED Manufacturing

Leave a CommentYou may also like:

Timeless Tools: The Standard Modern Lathe

Racer Machinery International: Journey Through Generations

Ontario Made Expertise for the Next Generation

What is DED?

How Does DED Work?

- 3D Model Creation: A 3D CAD model of the desired object is created.

- Layer Slicing: The model is sliced into thin layers, which serve as a blueprint for the 3D printing process.

- Material Deposition: A nozzle delivers powdered or wire-fed material to the build platform.

- Energy Source: A focused energy source, such as a laser or electron beam, melts the material as it is deposited.

- Layer-by-Layer Build: The melted material solidifies, forming a solid layer. This process is repeated layer by layer until the 3D object is complete.

Advantages of DED

- High-Quality Parts: DED can produce parts with excellent mechanical properties and surface finish.

- Repair Capabilities: It can be used to repair damaged components, extending their lifespan.

- Complex Geometries: DED can create intricate and complex shapes that are difficult to manufacture using traditional methods.

- Material Flexibility: A wide range of metals, including titanium, stainless steel, and nickel alloys, can be used in DED.

Disadvantages of DED

- Slower Build Speeds: Compared to some other 3D printing technologies, DED can be relatively slow.

- Post-Processing Requirements: Parts often require additional post-processing, such as machining or heat treatment.

- High Equipment Cost: DED systems can be expensive to purchase and operate.

Applications of DED

- Aerospace: Manufacturing of aircraft components, such as turbine blades and engine parts.

- Automotive: Production of prototypes and tooling for automotive components.

- Medical: Creation of custom implants and surgical tools.

- Energy: Repair of power plant components and manufacturing of energy-efficient parts.