Milling CNC Machines for Every Application

A CNC milling machine is a computer-controlled machine tool that uses a rotating cutting tool to remove material from a workpiece. By following pre-programmed instructions, CNC milling machines can produce highly accurate and complex parts. Key components include a spindle, worktable, axes, and a CNC controller. Milling operations such as face milling, peripheral milling, end milling, and drilling can be performed on these machines.

CNC milling offers numerous advantages, including precision, efficiency, flexibility, and repeatability. This versatility makes CNC milling machines essential in various industries, from automotive and aerospace to medical and manufacturing.

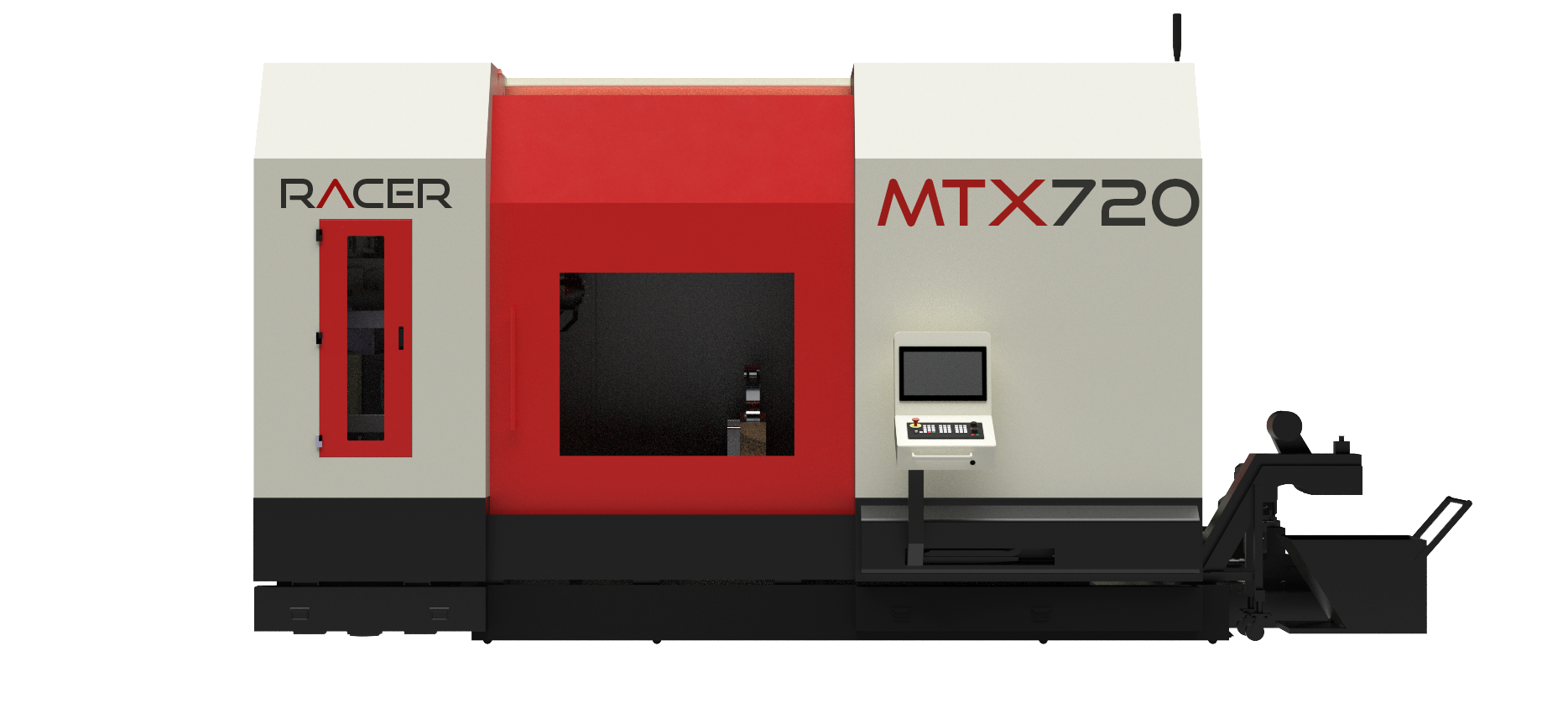

Vertical Milling

In vertical milling, the spindle and cutting tool are oriented vertically. This configuration is well-suited for precise and detailed work, such as drilling, tapping, and engraving. Vertical milling machines are often used for smaller, more intricate parts and can be more flexible in terms of workpiece orientation.

The choice between horizontal and vertical milling depends on factors like the size and complexity of the workpiece, the desired level of precision, and the specific machining operations required.

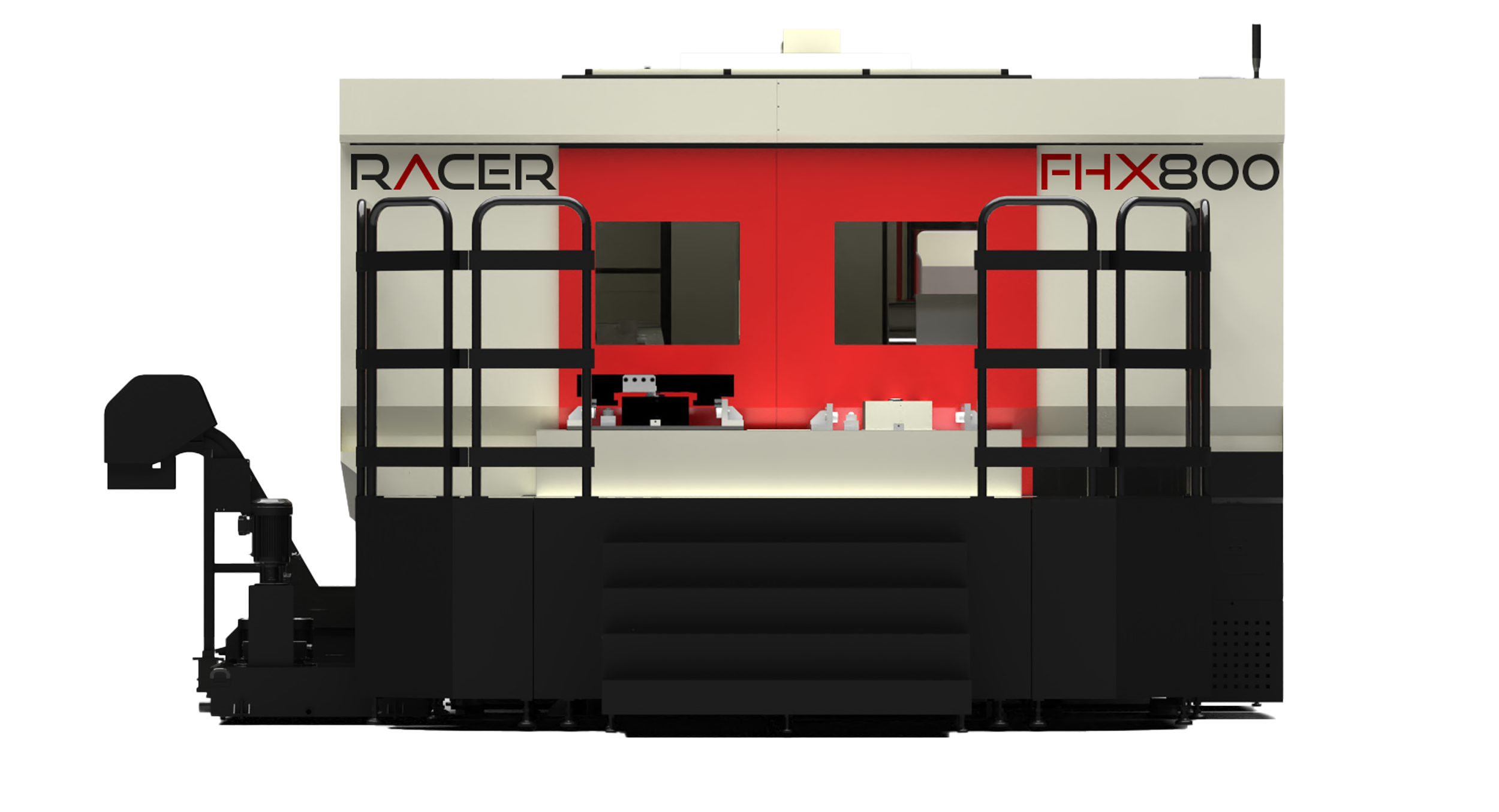

Horizontal Milling

Horizontal and vertical milling are two primary types of CNC milling operations that differ in the orientation of the spindle and cutting tool.

In horizontal milling, the spindle and cutting tool are positioned horizontally. This configuration allows for deeper cuts and greater material removal rates, making it ideal for machining large and heavy workpieces. Horizontal milling machines are often used for operations such as face milling, peripheral milling, and slotting.