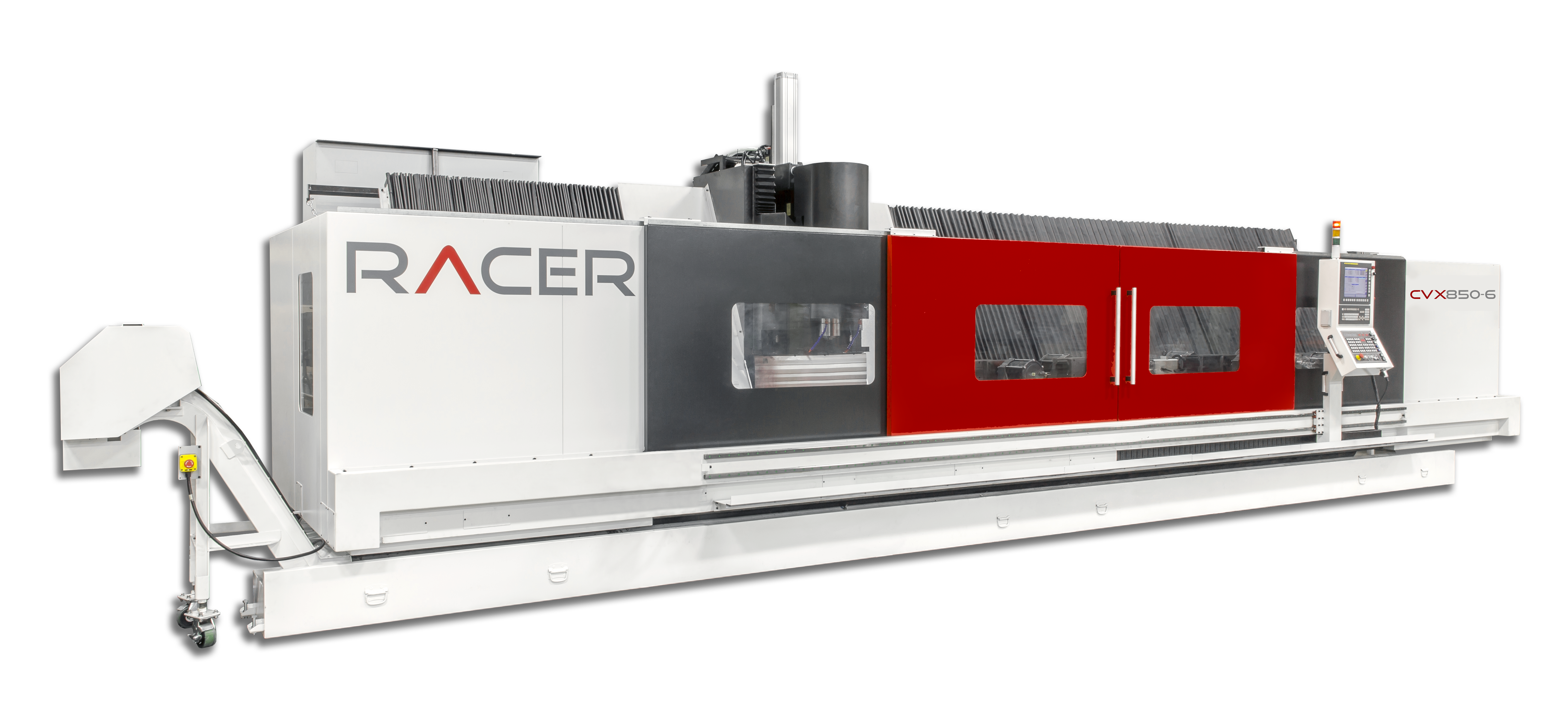

Precision vertical milling CNC machining for a variety of industrial applications.

| Specification | Range |

|---|---|

| Table Size (mm) | 1700 x 850 to 2200 x 850 |

| Travel Ranges (X x Y x Z mm) | 1500 x 900 x 850 to 2000 x 900 x 850 |

| Max. Table Load (kgs) | 2000 to 3000 |

| Spindle Speed (Rpm) Direct-Drive | 10000 to 12000 (15000) |

| ATC Tool Storage Capacity (PC's) | 20/24 to 24-32 (40) |

The VMX machine series represents a pinnacle in machining versatility, providing a spectrum of table sizes (1700 x 850, 2000 x 850, 2200 x 850 mm) to accommodate diverse workpieces. With a robust capacity to handle heavy loads (2000 to 3000 kgs), these machines ensure stability and precision in machining operations.

The flexibility extends to spindle speed options, allowing users to choose between belt, gear, and direct-drive configurations based on specific machining requirements and materials. The Auto Tool Changer (ATC) with plate/disk and disk/chain options, along with a dual-arm cam system, facilitates quick and efficient tool changes, enhancing overall machining productivity.

Custom machining center sizes available.

Looking for more details?

VMX Series Machining Center Features

Despite its powerful capabilities, the VMX series maintains a compact design, occupying a floor space ranging from 4050 x 2980 to 5000 x 2980 mm. This ensures efficiency in spatial utilization without compromising on performance. User-friendly features, such as rapid feed rates and straightforward tool selection, contribute to the ease of operation, making the VMX series an ideal solution for a wide range of machining needs, emphasizing practicality and operational simplicity.

-

Table Options: Versatile table sizes (1700 x 850, 2000 x 850, 2200 x 850 mm) for adaptable machining.

- Heavy-Duty Capacity: High table load (2000 to 3000 kgs) ensures stability and precision for large materials.

- Spindle Speed Variety: Flexible spindle speed options (belt, gear, direct-drive) for diverse machining requirements.

-

Efficient Tool Changes: Auto Tool Changer (ATC) with plate/disk and disk/chain options, featuring a dual-arm cam system for quick tool changes.

-

Compact and User-Friendly: Compact design with a floor space ranging from 4050 x 2980 to 5000 x 2980 mm. User-friendly features like rapid feed rates and straightforward tool selection for easy operation.

Ideal Applications

Technical Data

VMX Series

| Model | VMX 159 | VMX 179 | VMX 209 |

|---|---|---|---|

| TABLE | |||

| Table size (mm) | 1700 x 850 | 2000 x 850 | 2200 x 850 |

| Travel ranges (X x Y x Z mm) | 1500 x 900 x 850 | 1700 x 900 x 850 | 2000 x 900 x 850 |

| Max. Table Load(kgs) | 2000 | 2500 | 3000 |

| Spindle Nose to Table Surface (mm) | 100~950 | 100~950 | 100~950 |

| T-slot (Width x Distance x Number mm) | 18 x 150 x 5 | 18 x 150 x 5 | 18 x 150 x 5 |

| SPINDLE | |||

| Distance Between Column (mm) | ISO40 | ISO50 | ISO50 |

| Spindle Inner Diameter (mm) | Ø70 | Ø100 | Ø100 |

| Spindle Center to Column (mm) | 760 | 760 | 760 |

| Spindle Speed (Rpm) Belt | 40-8000 | 40-6000 (8000) | 40-6000 (8000) |

| Spindle Speed (Rpm) Gear | L40-2000, H2001-8000 | L40-1500, H1501-6000 | L40-1500, H1501-6000 |

| Spindle Speed (Rpm) Direct-Drive | 12000 (15000) | 10000 | 10000 |

| Draw Bar Force (kgf) | 950 | 2000 | 2000 |

| Main Motor (con/30 min Kw) | 11/15 | 15 / 18,5 | 15 / 18,5 |

| FEED RATE | |||

| Rapid Feed Rate (X/Y/Z m/min) | 24/24/12 | 24/24/12 | 24/24/12 |

| Feed Rate (X/Y/Z mm/min) | 10000 | 10000 | 10000 |

| AUTO TOOL CHANGER | ISO40 | ISO50 | ISO50 |

| ATC Type | PLATE / DISK | DISK / CHAIN | DISK / CHAIN |

| Cam Type | GENOVA/DUAL ARM | DUAL ARM | DUAL ARM |

| Tool Selection (Bi-direction) | ABSOLUTE/RANDOM | RANDOM | RANDOM |

| Tool Storage Capacity (PC's) | 20/24 | 24-32 (40) | 24-32 (40) |

| Max. Tool Diameter (mm) | Ø100 / Ø90 | Ø105 / Ø127 | Ø105 / Ø127 |

| Max. Tool Length (mm), Weight (kgs) | 250.8 | 350, 20 | 350, 20 |

| MISCELLANEOUS | |||

| Air Requiement (kg/cm2) | 6 | 6 | 6 |

| Voltage | 220V, 3Ph, 50/60Hz | 220V, 3Ph, 50/60Hz | 220V, 3Ph, 50/60Hz |

| Power Requirement (KVA) | 40 | 40 | 40 |

| Coolant Tnk Capcity (L) | 700 | 700 | 700 |

| Machine Weight (kgs) | 14000 | 15000 | 16000 |

| Machine Height (mm) | 3200 | 3200 | 3200 |

| Floor Space (L x W mm) | 4050 x 2980 | 4450 x 2980 | 5000 x 2980 |

| Packing Size (L x W x H mm) | 4350 x 3260 x 3550 | 4850 x 3260 x 3550 | 5300 x 3250 x 3550 |