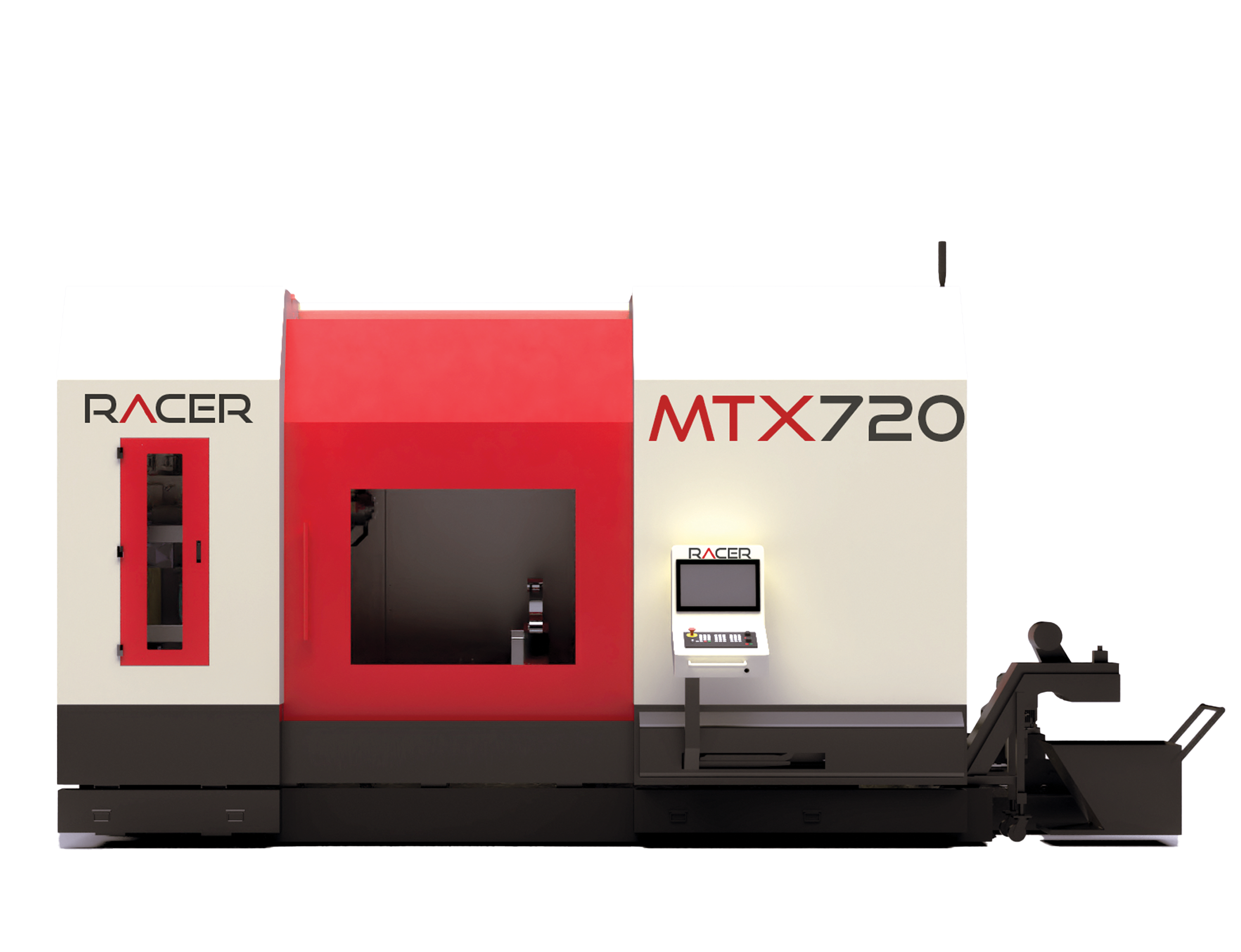

Multitasking CNC Machines for Every Application

Multitasking CNC machines are highly versatile and efficient tools that revolutionize manufacturing processes by combining multiple machining operations into a single setup. This integration of various functions significantly reduces setup times, minimizes manual intervention, and optimizes production efficiency.

Twin Spindle

These machines are equipped with two opposing spindles that work simultaneously to machine both ends of a workpiece. This capability significantly reduces cycle times and improves overall productivity. Twin spindle machines are particularly well-suited for high-volume production of symmetrical parts, such as automotive components, medical devices, and aerospace components.

Multi Column

Multi-column machines feature multiple vertical machining columns that can operate independently or simultaneously. This configuration allows for increased flexibility and the ability to machine multiple workpieces or different features on a single workpiece. Multi-column machines are ideal for complex part geometries and are commonly used in industries such as aerospace, automotive, and medical device manufacturing.

Mill-Turn

Mill-turn machines are a type of multitasking CNC machine that seamlessly integrates milling and turning operations into a single setup. This powerful combination significantly reduces setup times, minimizes manual intervention, and optimizes production efficiency.

Twin Spindle

Multi Column

Mill Turn