Turning CNC Machines for Every Application

A CNC turning lathe is a computer-controlled machine tool that rotates a workpiece, removing material to create cylindrical shapes and features. The machine uses a cutting tool that is precisely positioned and fed into the rotating workpiece to achieve the desired shape. Common turning operations include facing, turning, drilling, boring, and threading. CNC lathes offer high precision, efficiency, and repeatability, making them essential in various industries, such as automotive, aerospace, and manufacturing

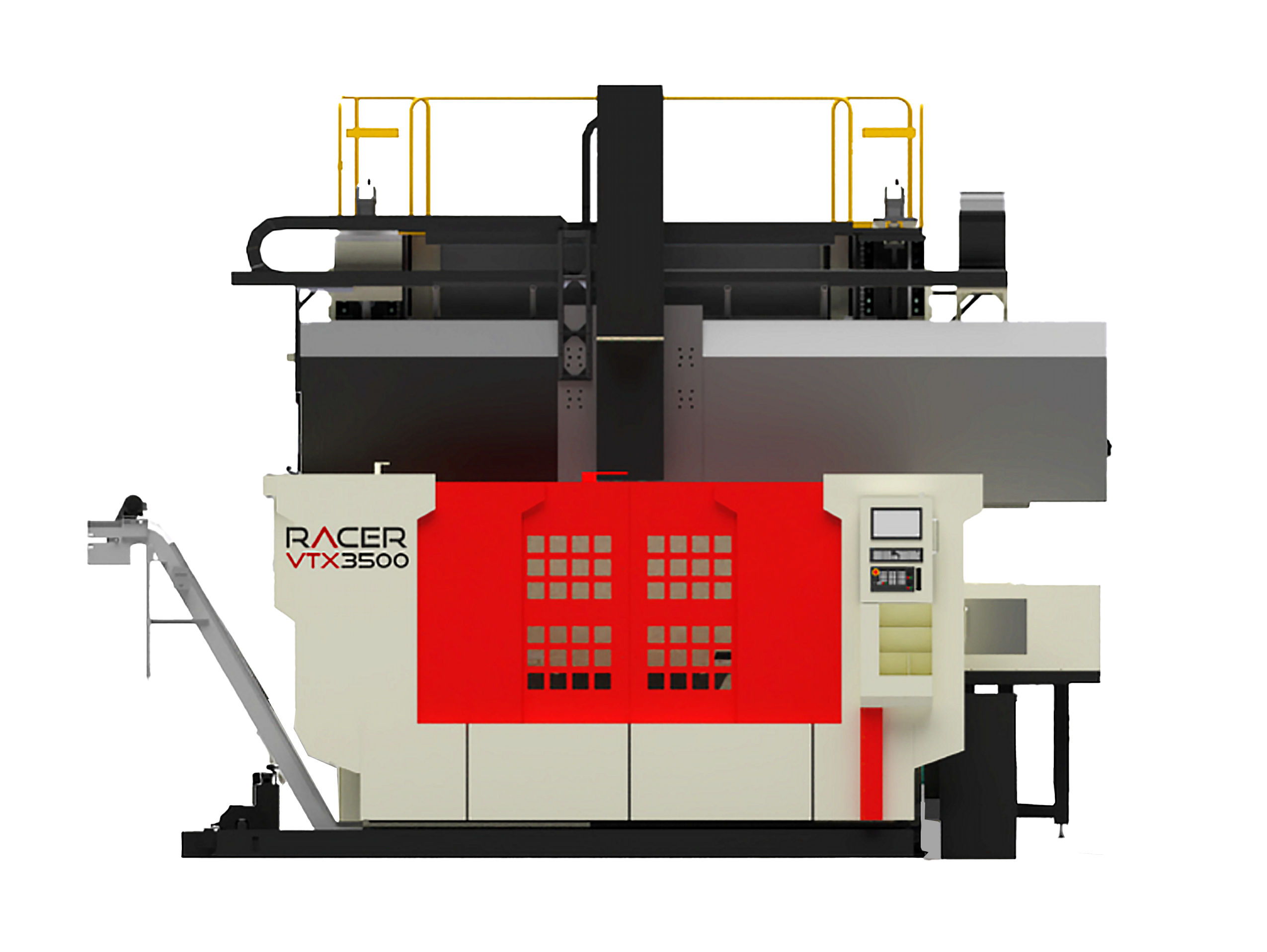

Vertical Lathe

A vertical lathe is a CNC machine tool designed for machining large, heavy workpieces. In a vertical lathe, the workpiece is mounted vertically on a rotating table, while the cutting tool moves horizontally. This configuration provides better stability and support for large and irregular-shaped workpieces. Vertical lathes are commonly used in industries such as shipbuilding, power generation, and heavy machinery manufacturing.

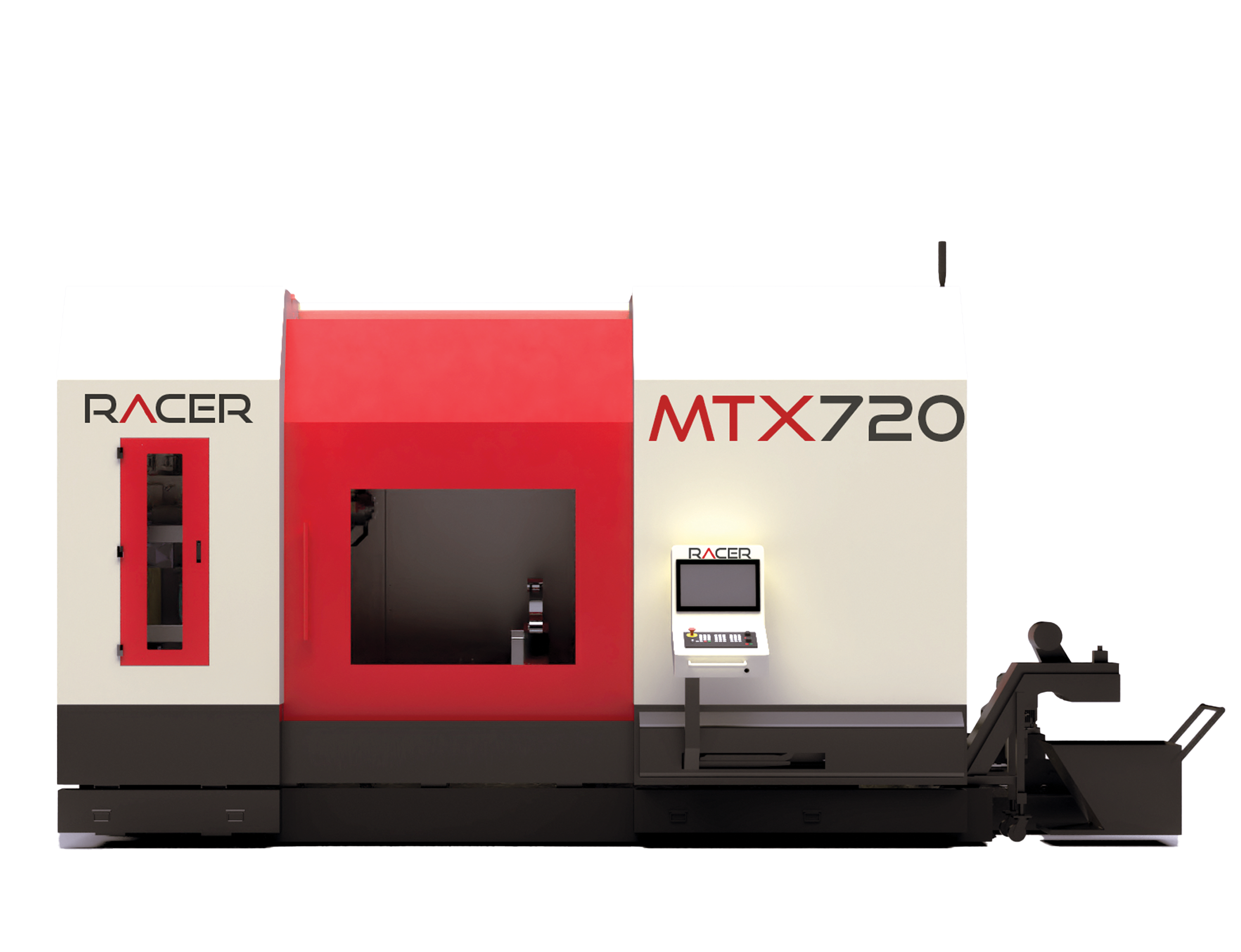

Mill Turn

A mill-turn machine is a versatile CNC machine tool that combines the capabilities of both milling and turning operations in a single setup. This integration allows for the production of complex parts with multiple features, eliminating the need for multiple setups and significantly reducing cycle times. Mill-turn machines are equipped with a rotating spindle and a movable tool turret, enabling them to perform a wide range of machining operations, including turning, milling, drilling, boring, and threading. This flexibility makes them ideal for a variety of industries, such as automotive, aerospace, and medical device manufacturing.

Mill Turn

Vertical Lathe