You may also like:

CNC Components: Mechanical Systems

Two Spindle Machines: Boosting Productivity

The Power of DED Manufacturing

Manufacturing Trends in 2025

The manufacturing industry is undergoing a transformative period, driven by technological advancements and shifting consumer demands. Here are some of the key trends shaping the future of manufacturing in 2025:

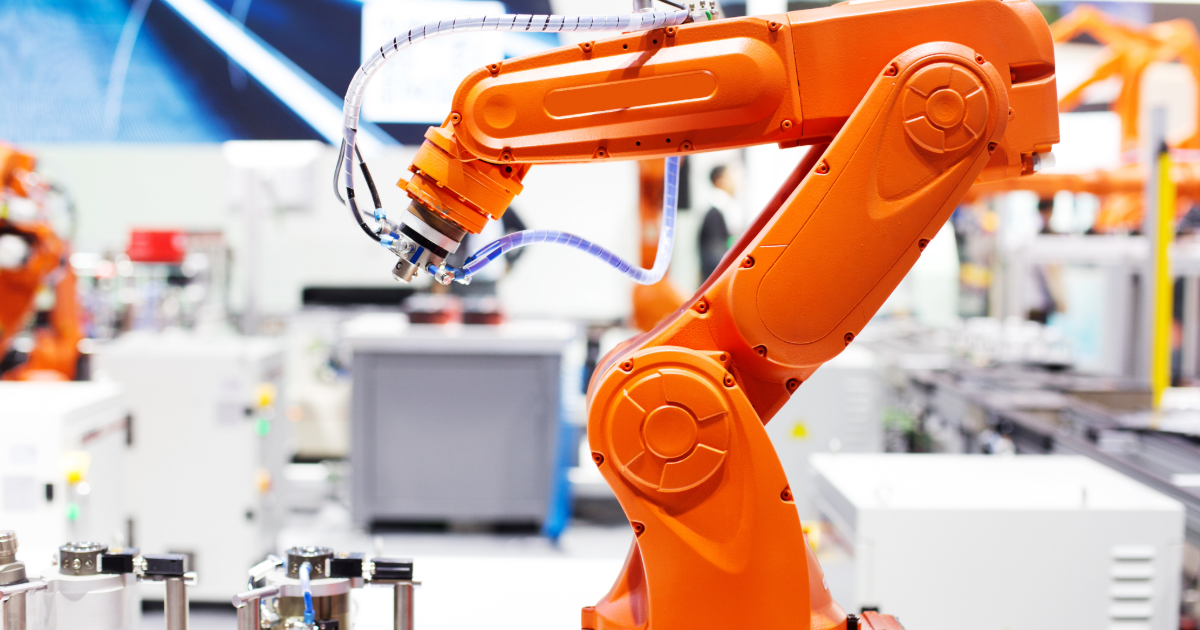

Increased Automation and Robotics

Automation and robotics are revolutionizing manufacturing processes, increasing efficiency and reducing labor costs. By automating repetitive tasks, manufacturers can allocate human resources to more strategic and creative endeavors. This trend is particularly evident in industries like automotive and electronics, where robotic arms are used for assembly, welding, and painting.

AI and Machine Learning Integration

Artificial intelligence and machine learning are empowering manufacturers to make data-driven decisions and optimize operations. AI-powered systems can analyze vast amounts of data to predict equipment failures, optimize production schedules, and improve quality control. This leads to increased efficiency, reduced downtime, and enhanced product quality.

Advancements in Multi-Axis Machining

Focus on Sustainability and Energy Efficiency

Sustainability is becoming a top priority for manufacturers. By adopting energy-efficient practices and reducing waste, manufacturers can lower their environmental impact and operational costs. Additionally, the use of sustainable materials and renewable energy sources is gaining traction.

Real-Time Monitoring and IoT Connectivity

The Internet of Things (IoT) is enabling real-time monitoring of manufacturing processes, allowing for predictive maintenance and optimized operations. By collecting and analyzing data from sensors and machines, manufacturers can identify potential issues before they escalate, reducing downtime and improving overall productivity.

Improved Software and Simulation Capabilities

Advanced software tools, such as CAD/CAM and simulation software, are empowering manufacturers to design and optimize products more efficiently. These tools enable virtual testing and prototyping, reducing the need for physical prototypes and accelerating product development cycles.

The Rise of On-Demand Manufacturing

On-demand manufacturing is reshaping the way products are produced. By leveraging 3D printing and other advanced technologies, manufacturers can produce customized products in small quantities, reducing lead times and inventory costs. This trend is particularly relevant for industries such as aerospace, automotive, and healthcare, where customization and personalization are becoming increasingly important.

Key Trends for 2025:

- Increased automation and robotics will lead to greater efficiency and productivity.

- AI and machine learning will drive innovation and improve decision-making.

- Advanced manufacturing technologies will enable the production of complex and customized products.

- Sustainability and energy efficiency will become even more critical.

- Digital technologies will revolutionize supply chain management and customer experiences.