You may also like:

Canadian Manufacturing Collaboration: Racer & Standard Modern

Adaptability and Digitalization for Future Success

Industry Solutions for the Military: Defense with Standard Modern

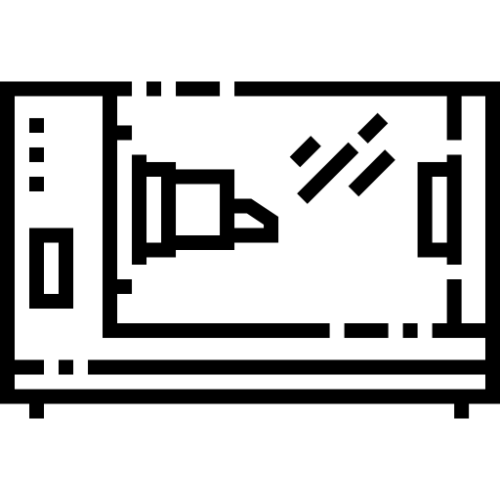

In the dynamic realm of manufacturing, innovation thrives on the convergence of tradition and technology. Enter Standard Modern Lathes, a brand that has embraced the power of automation through CNC (Computer Numerical Control) technology. As the heartbeat of modern machining, Standard Modern integrate CNC to automate processes, catapulting productivity to new heights while ensuring unwavering precision.

Join us as we embark on a journey through the world of Standard Modern Lathes, uncovering the remarkable fusion of CNC and automation that’s reshaping the landscape of manufacturing.

In manufacturing’s dynamic landscape, tradition meets technology with Standard Modern Lathes.

A Symphony of Precision and Control

Standard Modern Lathes infused with CNC technology orchestrate movements with unparalleled precision. Computer programs guide cutting tools, sculpting intricate shapes, profiles, and dimensions with exacting accuracy.

Enhanced Efficiency, Elevated Productivity

Standard Modern with CNC capabilities bring a new dimension to efficiency. Rapid tool changes, automated workpiece positioning, and reduced idle time between cuts propel productivity to unprecedented levels.

Consistency Woven in Automation

At the heart of CNC technology lies consistency. Standard Modern execute each cycle with unwavering precision, ensuring that every workpiece adheres to the highest standards set by the brand.

Embracing Complexity with Confidence

The amalgamation of CNC technology unlocks the ability to tackle complex designs and profiles. This synergy empowers machinists to create intricate patterns and custom threads that were once considered formidable challenges.

Versatility Redefined

The prowess of Standard Modern Lathes amplified by CNC technology transcends singular tasks. These lathes gracefully shift from one project to another, adapting to diverse workpieces and production demands effortlessly.

Minimizing Human Error, Maximizing Quality

CNC technology in Standard Modern Lathes minimizes the risk of human error. By following pre-set programs, these lathes ensure that deviations are minimized, resulting in products of uncompromised quality.

Standard Modern, with their integration of CNC technology, herald a new era of precision and automation. This isn’t just about machines; it’s about redefining the art of manufacturing with a brand that resonates with excellence.

The power of CNC technology in Standard Modern is an ode to progress, where each piece is a testament to the brand’s commitment to perfection and innovation. As automation takes center stage, CNC lathes lead the ensemble, crafting a future defined by precision, efficiency, and unmatched quality.