You may also like:

Advances in Multi-Axis Machining: Evolving Precision

Manufacturing Complex Components: Insights from Racer

Mechanics of CNC Machines: Mastering the Craft

Is 5-Axis Machining Revolutionizing Manufacturing?

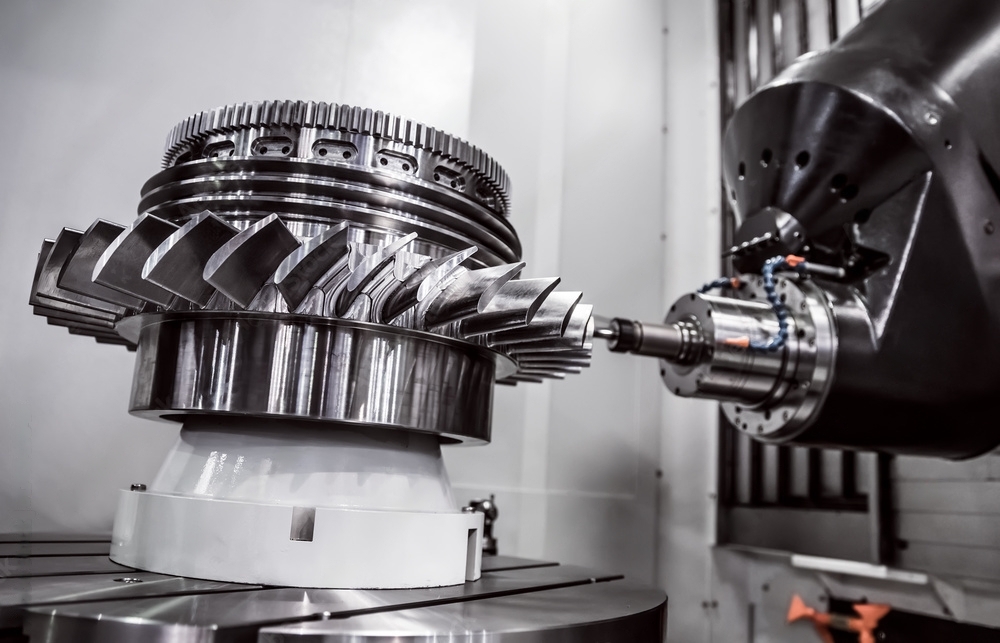

In the ever-evolving landscape of precision manufacturing, the ascent of 5-axis machining stands as a revolutionary leap forward. This cutting-edge technology has reshaped the possibilities of CNC machining, offering unparalleled versatility and precision. Join us on a journey as we explore the rise of 5-axis machining, unveiling a new dimension in the world of manufacturing.

Understanding 5-Axis Machining

Traditionally confined to the constraints of three axes – X, Y, and Z, CNC machining faced challenges when dealing with complex surfaces and intricate geometries. Enter 5-axis machining, introducing two additional rotary axes – A and B. This dynamic enhancement allows for unprecedented freedom of movement and the ability to approach a workpiece from multiple angles.

The fundamental advantage lies in its ability to move the cutting tool in five directions. This freedom enables machining from virtually any angle, eliminating the need for repositioning the workpiece. The result? Intricate and complex parts can be manufactured with fewer setups, reducing production time and enhancing overall efficiency.

Advantages

- Precision Redefined

- Single Setup Mastery

- Increased Tool Access

5-axis machining brings numerous advantages to precision manufacturing. With its ability to move in five directions, it ensures superior precision and accuracy, making it a top choice for intricate geometries. This technology reduces setups and boosts efficiency by completing parts in a single setup. The extended range of machining angles allows for the creation of complex surfaces, and the continuous tool contact results in a smoother finish. Additionally, 5-axis machining optimizes tool life, enhances versatility for producing customized parts, and reduces material waste. Its simultaneous movement of multiple axes speeds up production, making it valuable for meeting deadlines and managing large volumes.

Applications

- Aerospace Engineering Marvels

- Medical Precision at Its Finest

- Automotive Innovation Unleashed

Future Trends and Innovations

As adoption surges, the trajectory points towards continuous innovation. Integration with advanced software, enhanced automation, and real-time monitoring systems are shaping the future of this technology. These advancements aim to streamline processes, reduce downtime, and empower manufacturers with unprecedented control over the machining environment.

A New Horizon in Manufacturing

The rise marks a paradigm shift in precision manufacturing. What was once considered complex or unattainable is now achievable with a level of precision and efficiency that was previously unimaginable. As industries across the spectrum embrace this technology, we find ourselves at the dawn of a new era in machining. It has not only elevated the standards of precision manufacturing but has also opened doors to a realm of possibilities, where intricate designs and complex geometries are brought to life with unprecedented ease. The ascent of this machining is not just a technological advancement; it’s a transformative journey that propels us into a future where precision knows no bounds. Are you ready to explore this new horizon in manufacturing?