CNC Lathes: What’s on the Horizon?

Leave a CommentYou may also like:

Industry Solutions for the Military: Defense with Standard Modern

Standard Modern Lathes: CNC Technology

Industry 5.0: Mastering the Future

How Are Innovations Shaping the Future of CNC Lathe Technology?

In the ever-evolving landscape of machining, the ability to stay ahead of the curve is crucial for manufacturers seeking efficiency, precision, and a competitive edge. In this comprehensive exploration, we take a deep dive into the cutting-edge innovations that are shaping the future of CNC lathe technology.

From enhanced automation to intelligent control systems and seamless integration with Industry 4.0, let’s delve into how these advancements are revolutionizing turning operations and propelling CNC lathe technology into a new era of efficiency and precision.

Future Ready CNC

Automation Redefined: Embracing a New Era

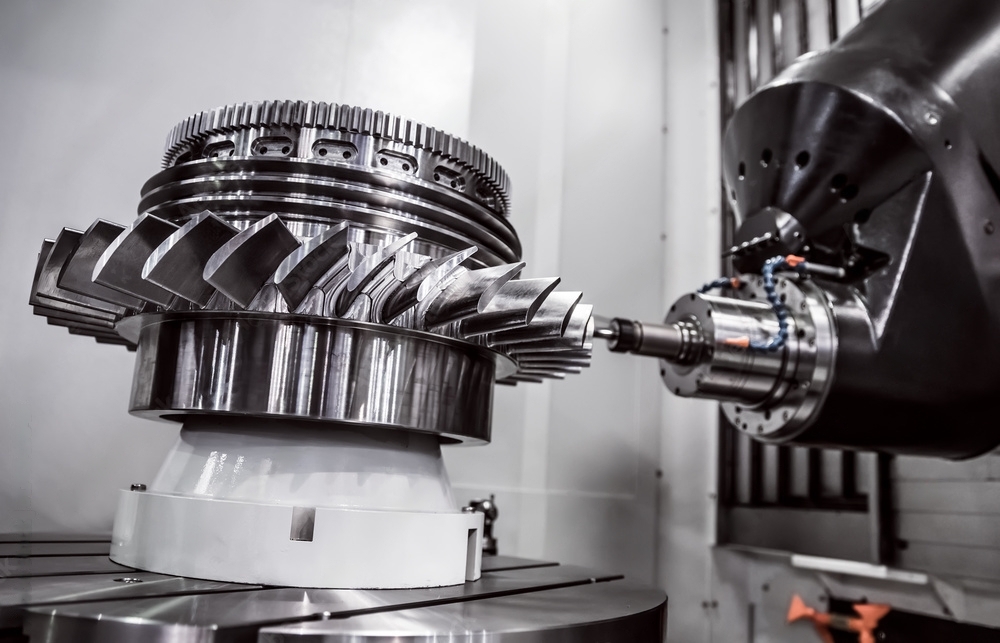

The dawn of automation has brought about a paradigm shift for CNC lathes. Today, robotic systems are at the forefront of innovation, working seamlessly alongside CNC lathes to automate tasks that were once manual.

Robotic Systems in Action

Imagine a CNC lathe equipped with a robotic arm that effortlessly loads raw materials, retrieves finished parts, and changes tools with precision. These robotic systems are not just tools; they are collaborators, enhancing the capabilities of CNC lathes and allowing them to operate continuously with minimal human intervention.

Increased Productivity and Efficiency

The integration of robotic systems with CNC lathes translates into increased productivity. With the ability to work 24/7 and perform repetitive tasks with unparalleled accuracy, these systems free up human operators to focus on more complex aspects of machining. The result is a significant boost in overall efficiency.

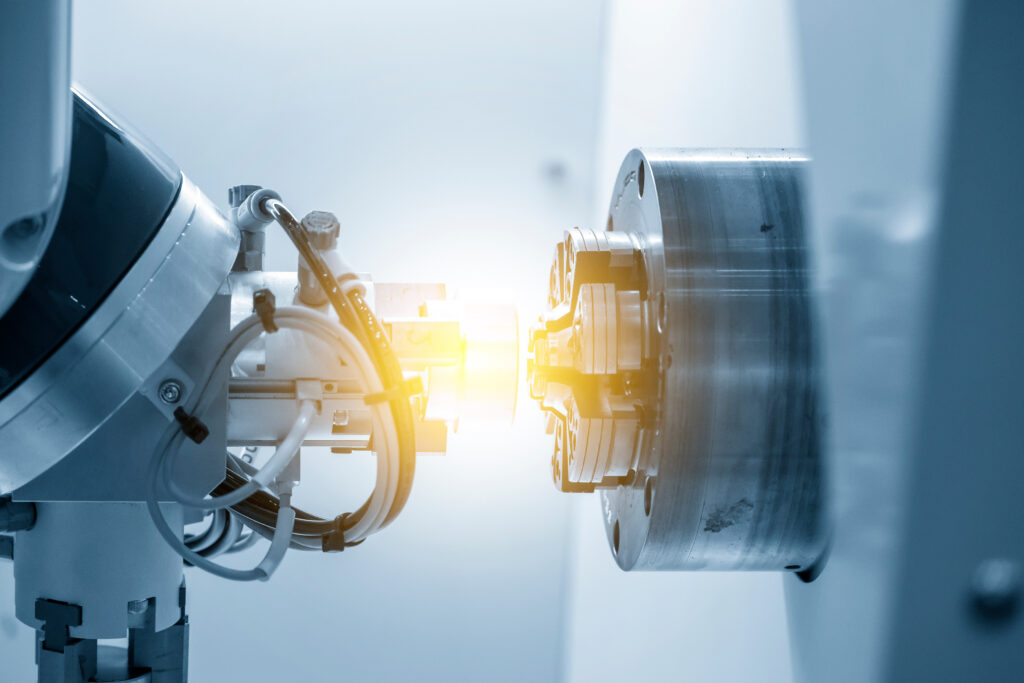

Intelligent Control Systems: Precision at Your Fingertips

Step into the world of intelligent control systems that are redefining the user experience in CNC lathe operations. Advanced control interfaces now offer more than just basic functionality—they provide intuitive programming, real-time monitoring, and adaptive machining capabilities.

The Evolution of Control Interfaces

Gone are the days of complex and cumbersome control interfaces. Today’s CNC lathe operators benefit from user-friendly interfaces that simplify programming tasks. These interfaces leverage touchscreens, intuitive software, and visual aids to streamline the programming process, making it accessible to a broader range of operators.

Real-Time Monitoring and Adaptive Machining

Intelligent control systems enable real-time monitoring of machining processes. Operators can track tool wear, detect anomalies, and make adjustments on the fly. Adaptive machining takes this a step further, allowing the CNC lathe to dynamically optimize cutting parameters based on real-time data. This level of control ensures precision and consistency in every operation.

Industry 4.0 Integration: A Connected Future

Witness the integration of CNC lathes into the fabric of Industry 4.0, where connectivity and data-driven decision-making take center stage. The marriage of CNC lathe technology with the principles of Industry 4.0 transforms traditional manufacturing processes into smart, connected systems.

Connectivity in Smart Factories

In smart factories, CNC lathes communicate seamlessly with other machines, sensors, and systems. This interconnected environment enables a flow of real-time data, fostering better decision-making and process optimization. From supply chain management to quality control, Industry 4.0 integration enhances overall operational efficiency.

Predictive Maintenance and Data Analytics

CNC lathe technology is no longer just about machining; it’s about predictive maintenance and data analytics. Through continuous monitoring and analysis of machine data, manufacturers can predict when maintenance is needed, reducing downtime and preventing costly breakdowns. Data analytics further provides insights into performance trends, allowing for continuous process improvement.

Increased Production Efficiency

In industries ranging from aerospace to automotive, the integration of automation and intelligent control systems has led to a substantial increase in production efficiency. CNC lathes equipped with these innovations can handle complex tasks with speed and precision, resulting in higher output and faster turnaround times.

Higher Product Quality

The precision achieved through intelligent control systems and Industry 4.0 integration translates directly into higher product quality. Manufacturers can consistently produce parts with tight tolerances, reduced defects, and superior surface finishes. This level of quality is essential in industries where precision is paramount, such as medical device manufacturing.

Future-Ready Manufacturing

The showcased innovations are not just visions of the future; they are already here, making a tangible impact in various industries. By using subheadings, bullet points, examples, and visuals, we aim to offer an immersive and engaging blog experience.