You may also like:

Timeless Tools: The Standard Modern Lathe

CNC Lathes: What’s On The Horizon

The Founding Fathers of Modern Manufacture

The evolution of threaded fasteners and lathes is a testament to human ingenuity and the relentless pursuit of precision. From the rudimentary tools of ancient civilizations to the sophisticated machinery of today, these devices have played a pivotal role in shaping the world we live in. Here we will explore the history of machined threads and lathes.

Early Beginnings

The concept of the screw thread, a fundamental component of threaded fasteners, can be traced back to ancient Greece. Archimedes, a renowned mathematician and inventor, is credited with developing the Archimedes’ screw, a device that utilized a helical screw to lift water. This early application of the screw principle laid the groundwork for future advancements in threaded fasteners.

The Industrial Revolution and Beyond

The Industrial Revolution marked a significant turning point in the development of threaded f

asteners and lathes. The increasing demand for precision-engineered components drove innovation and led to the development of more sophisticated machines.

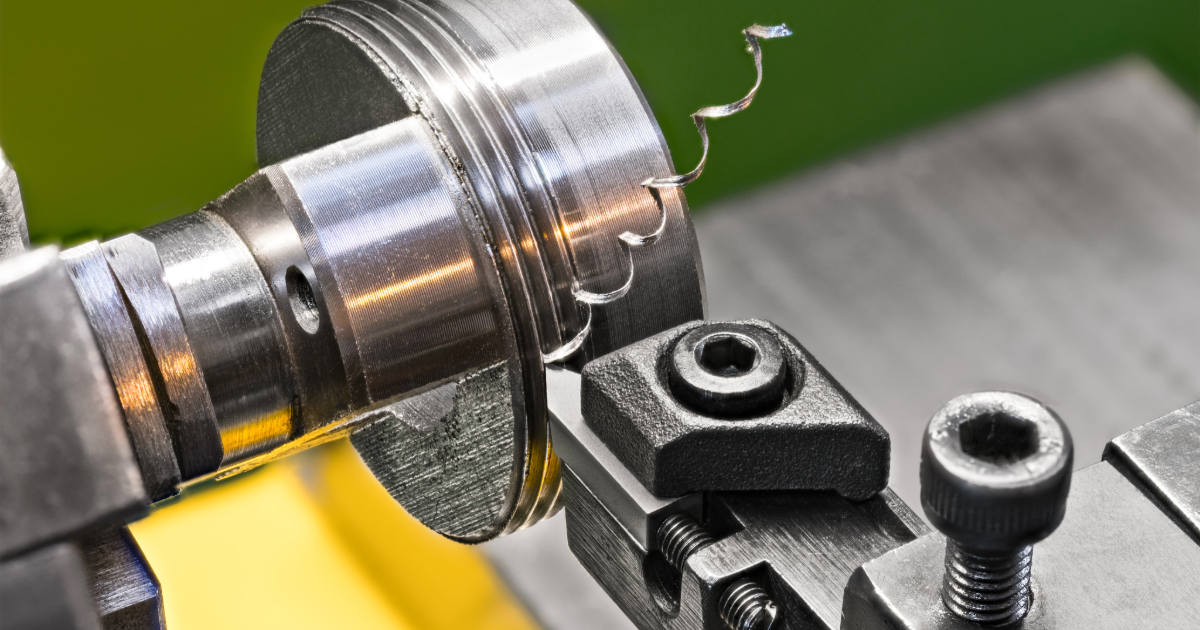

- Lathes: The lathe, a versatile machine tool, has been instrumental in shaping the modern world. Early lathes were simple devices that relied on manual labor to rotate the workpiece. However, with the advent of steam power and later electricity, lathes became more powerful and efficient. The invention of the screw-cutting lathe in the 18th century revolutionized manufacturing, enabling the production of standardized threaded components.

- Threads: The standardization of thread profiles, such as the Whitworth and Unified threads, was a crucial development in the 19th century. These standards ensured compatibility between components manufactured by different companies, facilitating mass production and assembly.

Modern History of Threads and Lathes

In recent decades, advancements in materials science, manufacturing technology, and computer-aided design (CAD) have led to significant improvements in threaded fasteners and lathes. High-strength alloys, such as stainless steel and titanium, have enabled the creation of stronger and more durable fasteners. Additionally, the development of precision machining techniques, including CNC machining, has allowed for the production of complex threaded components with exceptional accuracy.

Today, threaded fasteners and lathes continue to evolve, driven by the demands of industries such as aerospace, automotive, and medical. As technology advances, we can expect to see even more innovative and efficient solutions for connecting and shaping materials.