You may also like:

Directed Energy Deposition: Materials and Uses

Wear Resistant Designs: Engineering for Longevity

Tooling Selection: Optimizing for Performance and Tool Life

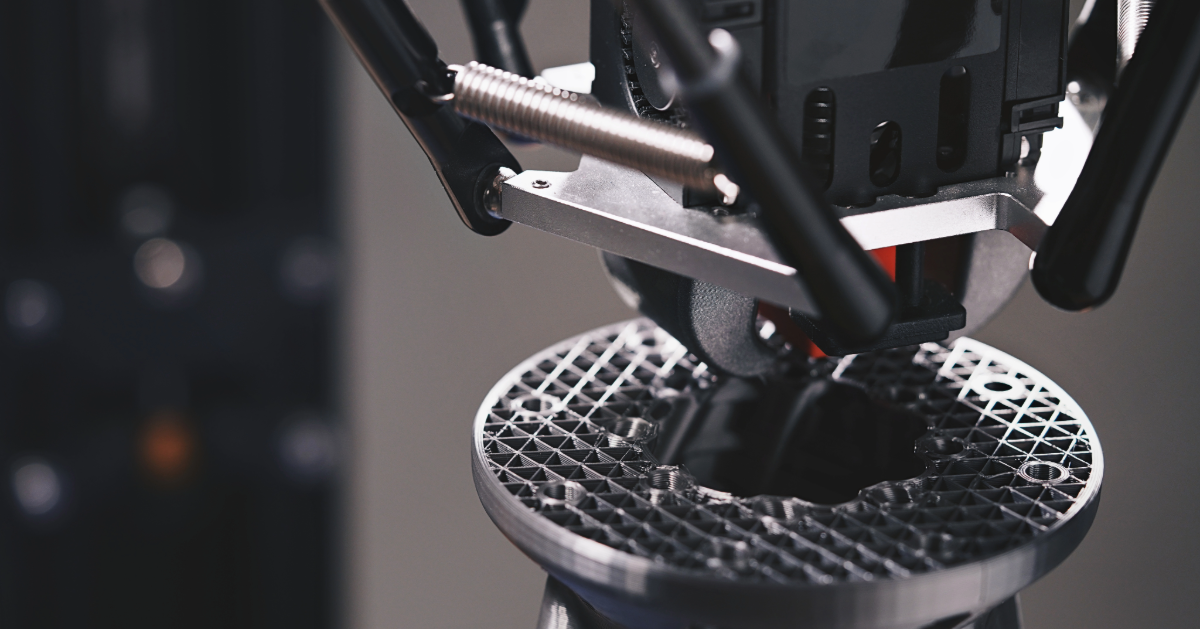

As sustainability becomes a critical focus across global industries, manufacturers are turning to advanced technologies to reduce waste, energy consumption, and carbon emissions. One emerging solution is hybrid machining — the integration of additive and subtractive manufacturing processes within a single system.

This combined approach brings efficiency and flexibility to the production floor, but how sustainable is hybrid machining in practice? Here’s a closer look at its environmental benefits, challenges, and potential for driving greener manufacturing.

How Hybrid Machining Supports Sustainability

Hybrid machining combines additive and subtractive processes into a single, integrated system — and with it comes new opportunities to improve sustainability across the manufacturing lifecycle. From reducing material waste to optimizing energy use and enabling smarter production planning, this approach offers practical pathways for manufacturers to lower their environmental impact while maintaining high productivity and precision.

Increased Production Efficiency

Optimizing production planning is key to reducing waste and emissions. Hybrid systems help manufacturers better manage material usage and recycling strategies. Research has shown that by using mathematical modeling and optimization algorithms, companies can minimize both economic costs and carbon output during production planning.

Smarter Production Planning

The system uses strategically placed temperature sensors throughout the machine. These sensors continuously collect thermal data during operation. The data is processed using a compensation model that calculates how heat affects various components and determines how those changes will influence machining accuracy.

The system then adjusts the machine’s control signals in real time to offset the impact of thermal distortion. In essence, the machine compensates for its own physical changes — maintaining consistent precision regardless of operating temperature.

Reduced Energy Use

Modern hybrid machines are increasingly equipped with energy-efficient technologies, such as variable-speed drives and intelligent monitoring systems. These features help optimize power usage, particularly during idle or low-load periods, contributing to a lower overall energy footprint.

Integration of Advanced Technologies

Technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) are transforming hybrid machining systems into smart, responsive platforms. These tools support real-time data collection and analysis, improving process control and reducing resource waste.

Digital Supply Chain Integration

Hybrid machining aligns well with the digital supply chain model. Blockchain, advanced analytics, and autonomous systems offer improved transparency, better material sourcing decisions, and quicker responsiveness. In some cases, hybrid additive manufacturing has been used to produce functional components—such as drones—on demand, supporting just-in-time delivery and inventory reduction.

Sustainability Challenges in Hybrid Manufacturing

While hybrid machining offers clear advantages for improving efficiency and reducing waste, achieving true sustainability requires a deeper look at the challenges it presents. From energy-intensive processes to material sourcing and post-production demands, manufacturers must navigate several hurdles to make hybrid operations genuinely eco-friendly. Understanding these obstacles is essential to developing responsible, future-ready manufacturing strategies.

High Energy Consumption

Certain processes, like laser sintering, can be highly energy-intensive. Studies show that some hybrid techniques may consume more energy than conventional methods without efficiency improvements.

Material Sourcing Concerns

The environmental impact of hybrid machining depends heavily on the materials used. Polymers derived from oil and rare metals often involve unsustainable extraction methods and are difficult to recycle.

Limited Recyclability

Powders and composite materials used in hybrid additive processes often have limited reuse potential due to contamination or degradation during use.

Cost Barriers

High initial investment and operating costs remain a significant barrier to widespread adoption. In addition, complex systems often require highly trained operators and specialized maintenance.

Post-Processing Demands

Quality control and post-processing steps such as heat treatment, polishing, or deburring may involve significant energy use, which can offset the environmental benefits gained earlier in the process.

Balancing Innovation and Environmental Responsibility

Hybrid machining has the potential to reshape manufacturing by improving efficiency, flexibility, and resource optimization. However, realizing its sustainability benefits depends on thoughtful implementation. Manufacturers must address challenges related to energy usage, material sourcing, and cost in order to fully align hybrid machining with environmental goals.

As the technology continues to evolve, investments in smart systems, recyclable materials, and energy-efficient practices will be essential to building a more sustainable future in manufacturing.