Machining Center – FHX Series

-

Machine Description

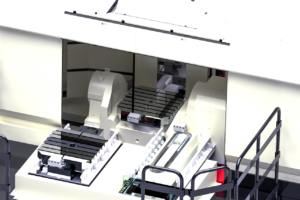

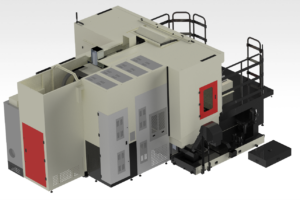

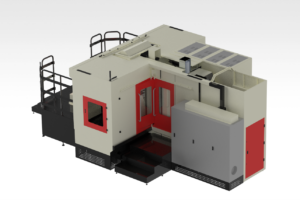

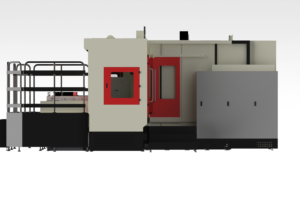

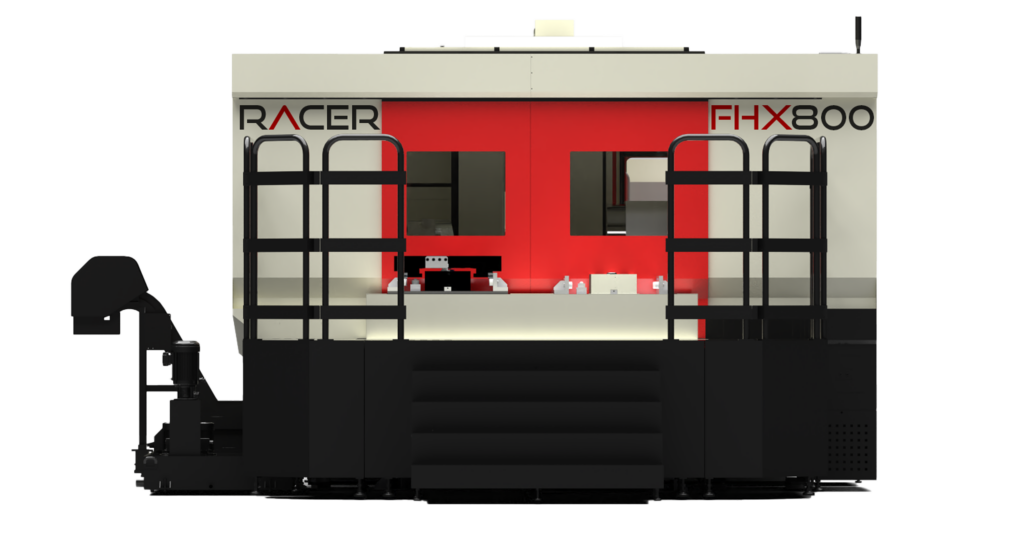

FHX Series – Horizontal Machining Center

The FHX Horizontal Machining Center series is a versatile solution for different machining needs. With tables in various sizes and extensive travel ranges, it can handle a wide range of workpiece sizes. The spindle options, including ISO40 and CAT50/HSKA100, enable efficient machining at high speeds.

Equipped with high-speed motors, the FHX series ensures fast and precise movements, and its advanced tool-changing system supports uninterrupted machining with various tool capacities. Overall, the FHX series is a reliable choice for diverse industrial applications.

-

Key Highlights

- Diverse table sizes: Ranging from 500 x 500 mm to 1600 x 1320 mm, catering to various workpiece dimensions

- Extensive travel ranges: X-axis from 650 mm to 3000 mm, Y-axis from 560 mm to 2200 mm, and Z-axis from 560 mm to 1420 mm

- Flexible spindle options: ISO40 and CAT50/HSKA100 spindles with speeds up to 15,000 rpm for efficient machining

- High-speed servo motors: Achieving rapid feed rates of 30/24/30 m/min (X/Y/Z) and 41/41/41 m/min for selected models

- Advanced tool-changing system: Featuring a chain or chain/matrix ATC type, supporting up to 40 to 360 tool storage capacity for uninterrupted machining operations

-

Industry Applications

Aerospace Industry

Achieve precision in the aerospace realm with our CNC solutions, delivering seamless and efficient machining processes tailored to the unique demands of the aerospace industry.

Automotive Industry

Enhance automotive precision through our CNC solutions, offering streamlined solutions for efficient and precise machining processes in the automotive industry.

Mechanical Engineering

In the field of CNC mechanical engineering solutions, our focus is on delivering reliable tools that contribute seamlessly to the precise crafting of components. We emphasize practicality and efficiency to meet the specific demands of mechanical engineering applications, prioritizing precision and reliability in our approach.

Technical Data

| MOVING COLUMN T-STYLE | ||||

| TABLE | FHX 500/FHX500A | FHX 800 | FHX 1250 | FHX 1600 |

| Table Size & Number (mm) | 500 x 500 | 800 x 800 | 1250 x 1000 | 1600 x 1320 |

| Travel X | 650 | 1600 | 2200 | 3000 |

| Travel Y | 560 | 1230 | 1800 | 2200 |

| Travel Z | 560 | 1020 | 1200 | 1420 |

| Screw size (Size x Pitch mm) | 18 x 100 x 5 | |||

| Max. Table Load (kg) | 400 | 2500 | 5000 | 8000 |

| Max. Workpiece Size (W x H mm) | Ø630 x 610 | |||

| Spindle Center to Table surface (mm) | 50 | |||

| Spindle Nose to Table Center (mm) | 100 | |||

| Table Index (deg) | 1° (0.001°) | |||

| Method of Pallet Changer | – | |||

| SPINDLE | ||||

| Spindle Taper | ISO40 | CAT50/HSKA100 | ||

| Spindle Inner Diameter (mm) | Ø70 | |||

| Spindle Speed (rpm) Belt | 8000 | |||

| Spindle Speed (rpm) Gear | 8000 | 6000 | ||

| Spindle Speed (rpm) Built-in | 15000 | |||

| Main Motor (con/30 min Kw) | 15HP | |||

| AXIS SERVO MOTOR | ||||

| Rapid Feed Rate (X/Y/Z m/min) | 30/24/30 | 41/41/41 | ||

| Feed Rate (X/Y/Z/ m/min) | 10 | |||

| X Axis Rated Torque (Nm) | 10 | |||

| Y Axis Rated Torque (Nm) | 10 | |||

| Z Axis Rated Torque (Nm) | 10 | |||

| B Axis Rated Torque (Nm) | 10 | |||

| B Axis Max. Rpm | 16.6 | |||

| AUTO TOOL CHANGER | ||||

| ATC Type | CHAIN | CHAIN/MATRIX | ||

| Cam Type | ARM | |||

| Tool Selection (Bi-direction) | RANDOM | |||

| Tool Storage Capacity (PCs) | 40 | {62/88/128/160/240} {120/180/240/360} | ||

| Max. Tool Diameter (mm) | Ø76 | |||

| Max. Tool Length | 300 | |||

| Max. Tool Weight | 8 | |||

| MISCELLANEOUS | ||||

| Air Requirement (kg/cm2) | 6 | |||

| Hydraulic Requirement (kg/cm2, L) | 35, 60L | |||

| Voltage | 220 | |||

| Power Requirement (KVA) | 40 | |||

| Coolant Tank Capacity (L) | 300 | |||

| Machine Weight (kgs) | 6500 | 26000 | 38000 | 66000 |

| Machine Height (mm) | 2425 | |||

| Floor Space (L x W mm) | 3055 x 4560 | |||

| Packing Size (L x W x H mm) | 2200 x 2900 x 2500 | |||